Dune season is just a few months away, and to get in the spirit of sand, we headed to Funco Motorsports in Rialto, California, to check out some of the baddest sand cars. Funco sand cars have one of the most identifiable styles in the dunes, but we wanted to check out what goes into these vehicles.

Funco is a family-owned and operated business that has been in business since Gil George founded the company in 1968. When Gil first learned how to weld, he took what he learned from building drag racing chassis and put it into making a dune buggy for himself.

People began to take notice of his new dune buggy, and before he knew it, people wanted to buy them. On any given day, you can find at least eight George’s working side by side, from the creators to children and grandchildren.

We stopped by the shop and got a tour of what was going on from Grant George. The shop was loaded with sand cars in different stages of the build process, allowing us to see how everything went together.

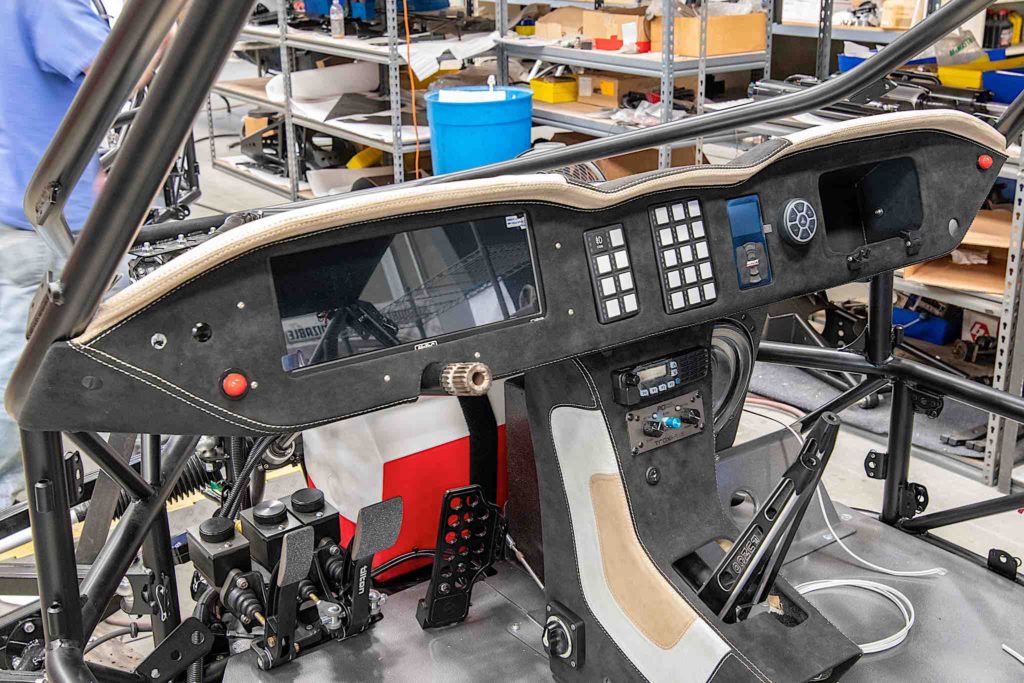

Funco has exclusive design features that get the latest in technology, audio, and raw horsepower into their vehicles to make them not only great looking but enjoyable in the dunes. It is hard for photos to do these vehicles justice, especially the attention to detail taken during the build process.

"There are many great things about building our sand cars," Grant said. "But the most enjoyable part about building our sand cars is turning our customer's vision into reality."

In a design process that starts months before any tubes are cut or welded, Grant works with each customer to help get the ideas and goals down to ensure that the build is to the customer's liking. Everything is figured out, from paint color to engine options, and a plan is laid out.

"We put the customer first," Grant said. "When you buy a Funco, you become part of the family."

When a build starts, it begins on the chassis jig table, where the model sand car takes shape over the two weeks. Every tube is laid out and tacked together before fully welded and moving to the next stage.

After the car chassis is built, it moves over a stall and begins to get tabbed out for the engine and transmission, seats, and suspension. Everything on the vehicle will have a tab or bracket welded to the chassis so it can be secured during final assembly.

Once all the welding is completed, the chassis is sent out to be powder coated. When the chassis returns, it is put into the assembly stage, where everything on the vehicle is installed. This is where the drivetrain is installed, shocks, audio system, dash, and seats end up in their home.

When the body panels arrive back from paint, final assembly can begin. The car starts to take its final shape with all the pieces together. Funco sand cars range in price from $185,000 to $285,000, depending on the selected options.

In addition to building new sand cars, if cars are damaged or need a color change, Funco can handle them in-house. No one knows these cars better than the people who built them in the first place.

We thank Funco Motorsports for allowing us to stop and check out the shop. For more information on Funco Motorsports, be sure to visit their website.